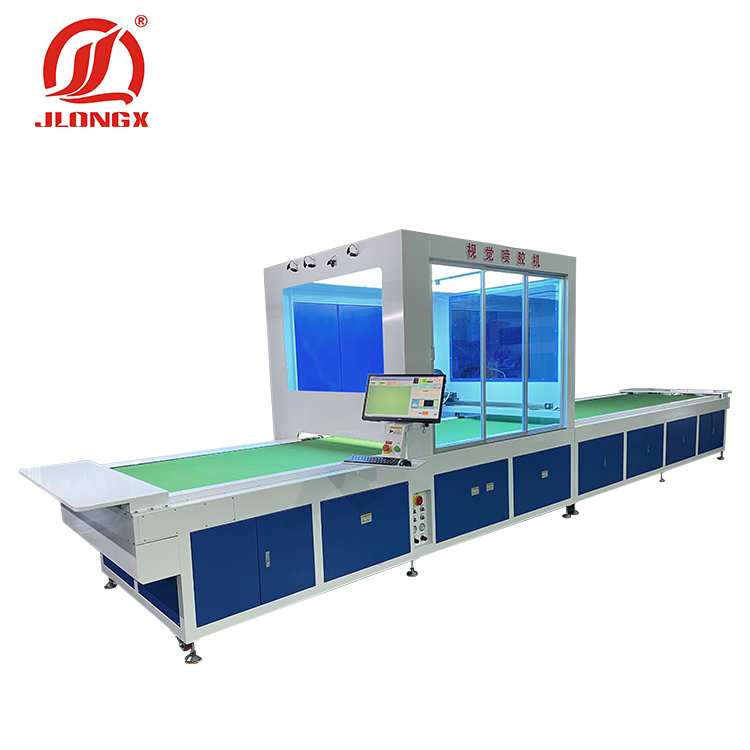

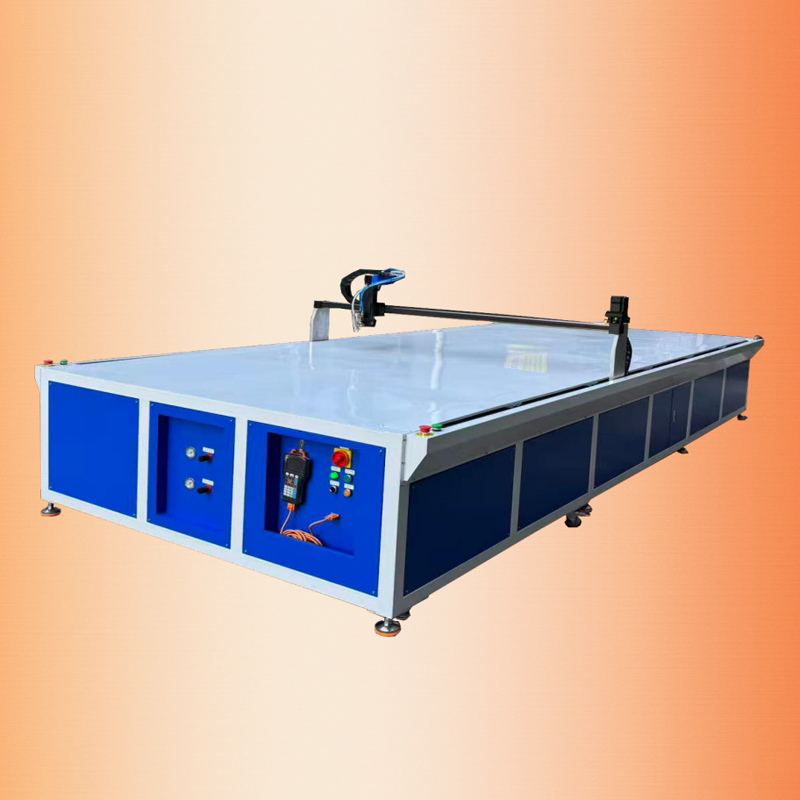

JL-1390LS Large scale assembly line visual glue spraying machine

Description

Product Features:

1. Large Range: The glue spraying range is 1.3 meters long and 90 cm wide.

2. Conveyor: Automated conveying system with four sections, including an oven, dries out the glue during spraying, allowing immediate operation.

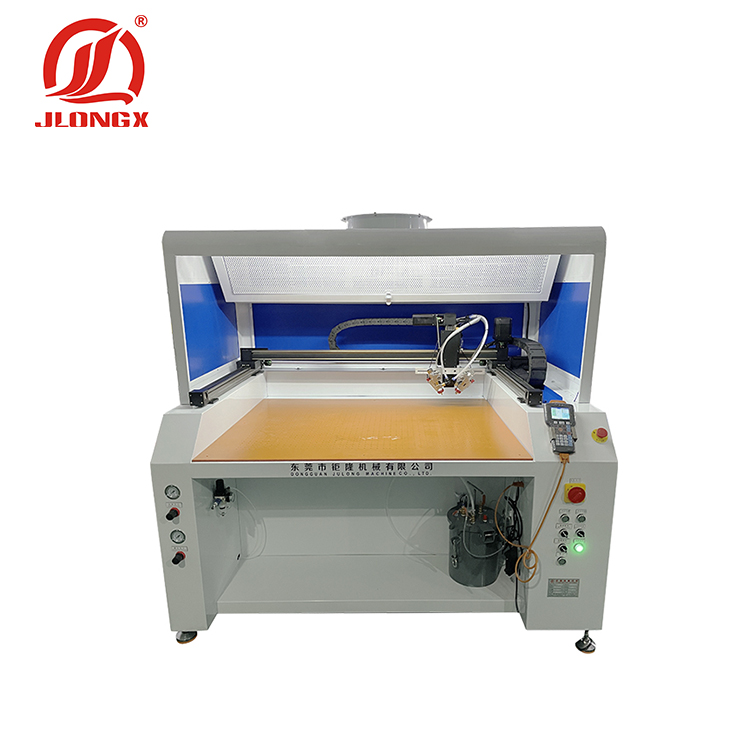

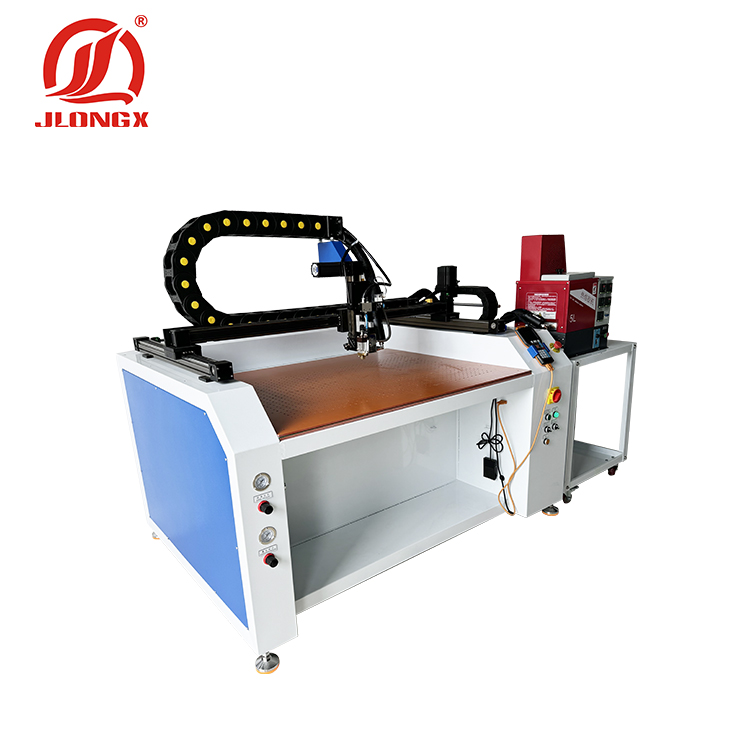

All-Sheet Metal Frame: The frame is a welded sheet metal structure, ensuring it remains stable during long-distance transport. No assembly is required; simply plug in and use.

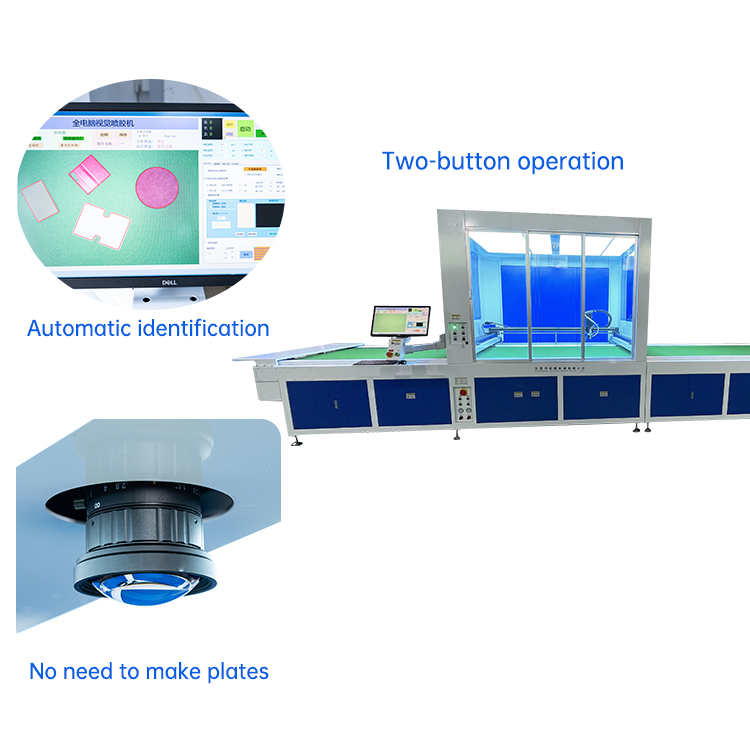

3. Automatic Identification: This machine uses a 30-megapixel camera that can capture and identify the material’s contour within 1 second and generate a glue spraying path.

4. No Pattern Required: No pattern editing is required; any shape and color can be placed on the machine platform. It can identify the product’s trajectory without saving or importing drawings.

5. Free Dropping: Materials can be dropped into the machine at will, without requiring a fixed location; the machine will automatically find them.

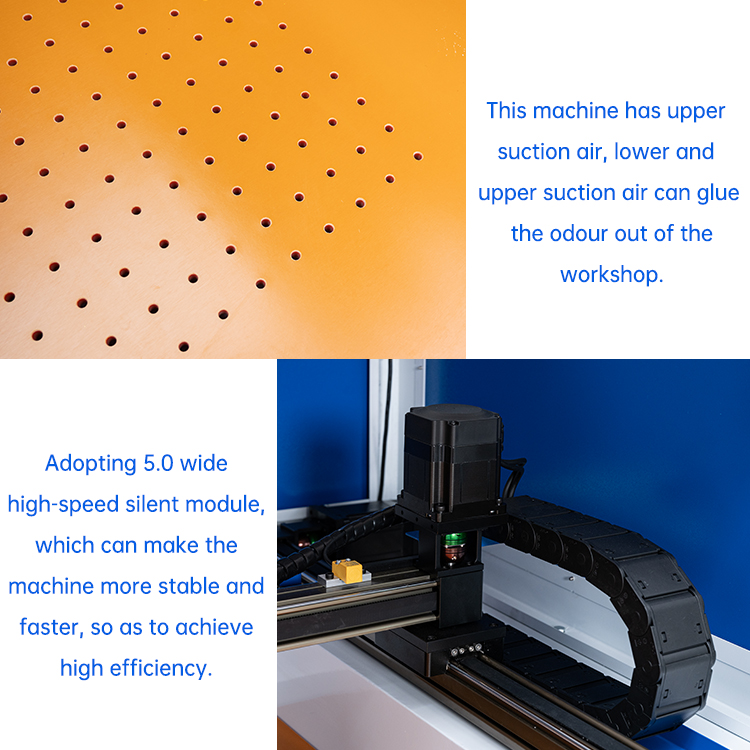

6. Automatic Suction: The machine is equipped with four fans for suction, which absorbs the material and prevents it from moving during operation.

7. Module: Utilizing a 5.0mm wide, high-speed, silent module, this machine is more stable and efficient, achieving high efficiency.

8. High Speed: Utilizing a 750W high-power full-servo motor, the machine can achieve a maximum spray speed of 1200 mm/s per distance.

9. Improve efficiency and save labor costs. The fast coating speed can eliminate 5-8 people, effectively improving production efficiency and reducing labor costs.

10. Save glue and reduce costs. The stable, controlled gluing system and adjustable glue spray head can better meet the user’s different glue spray width requirements, capable of spraying glue with a width of 3-15mm along the material.

11. High operating efficiency, uniform and thin glue spray, saving approximately 20% of glue, resulting in high efficiency.

12.Easy operation, automated material handling, and automated visual positioning.

A vision system is a set of devices that use visual information to perform specific functions. Adding vision sensors aims to give these devices human-like vision, thereby increasing their intelligence and improving production line efficiency and product quality.

Machine vision can be used to perform tasks in hazardous environments where humans are unable to perform or where the human eye cannot meet quality requirements.

Therefore, machine vision technology can increase the automation and flexibility of production lines. Using cameras to automatically capture workpiece contours reduces rounding errors and is simple and easy to understand.

13. Wide adaptability: Within the effective spraying range, it can identify materials of different colors, shapes, and locations, better adapting to the specific material characteristics required during the production process.

14. Environmentally friendly and energy-saving, the equipment features an exhaust system that absorbs glue odors generated during spraying.

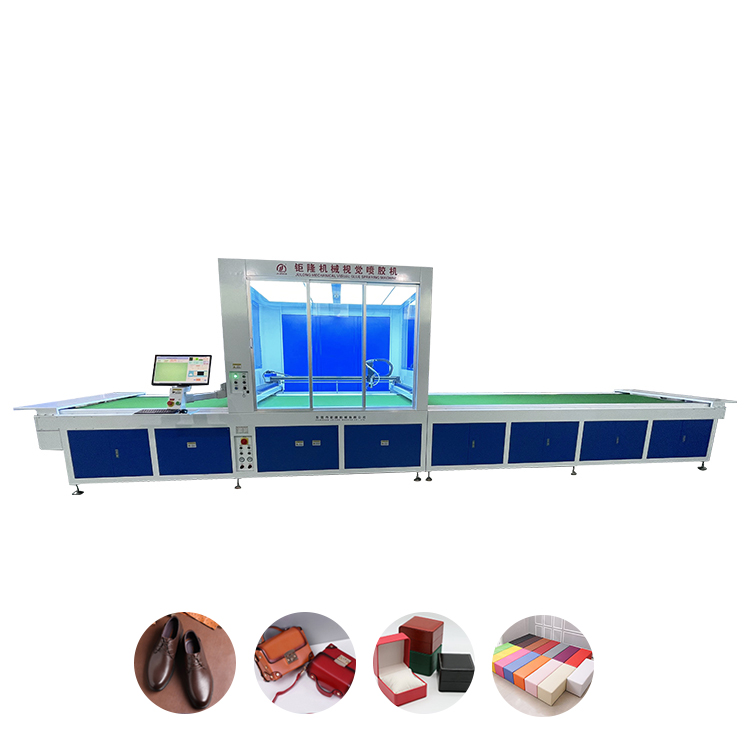

Applicable to:

shoe factories, luggage factories, leather bag factories, gift jewelry packaging box factories, leather goods factories, electronic product leather case factories, jewelry factories, furniture factories, glasses case factories, automobile interior decoration factories and other industries.

Product Specifications:

Spray Width: 1300 x 900mm

Voltage: 220V

Motor Power: 7kW

Machine Dimensions: 8000 x 1400 x 2100mm

Net Weight: 1500kg