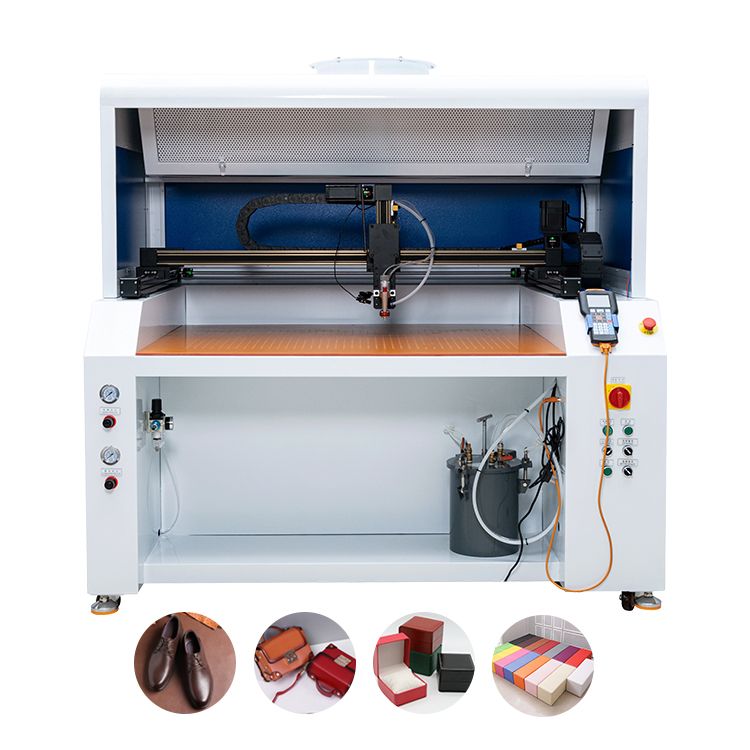

JL-10060R Fully automatic hot melt adhesive spraying machine

Description

This fully automatic hot melt adhesive dispenser utilizes advanced computer-controlled technology for exceptional ease of operation. It’s suitable for adhesive applications across a wide range of industries, including automotive seats, aircraft sound insulation, furniture, protective gear, sporting goods, mattresses, leather goods, packaging, wallets, handbags, luggage, and accessories.

1. Simple operation: Programming can be done on-site using a touchscreen computer or on a computer using applications like CAD/CoreLDRAW, then converted to DXF format and downloaded to the machine. Easy to learn and understand.

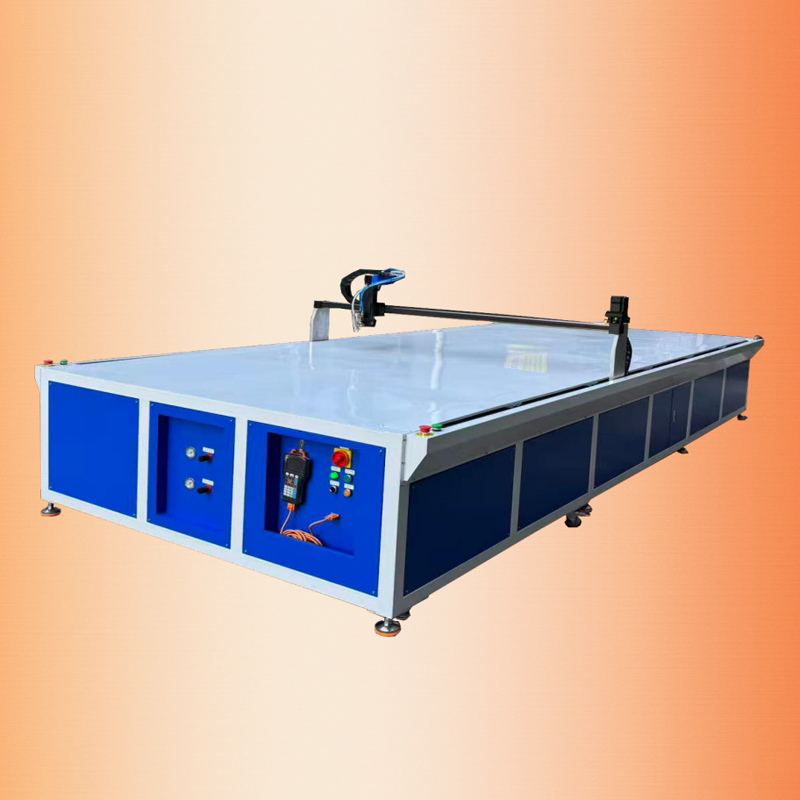

2. High speed: The bridge-type platform structure allows for simultaneous operation and material unloading, achieving adhesive dispensing speeds 5-6 times faster than manual operation.

3. Up to four axes can be linked, enabling not only forward and backward, but also left and right movement, as well as three-dimensional, inclined, and single-sided adhesive application.

4. High precision and uniform adhesive application, eliminating glue push and dead glue.

5. The glue barrel is completely sealed, preventing glue from drying out. This reduces waste and prevents the release of toxic gases that could pollute the work environment. 6. Compatible with a wide range of glues, including white glue, all-purpose glue, PUR glue, and hot melt glue.

7. Large working range, capable of spraying up to 1000mm x 600mm.