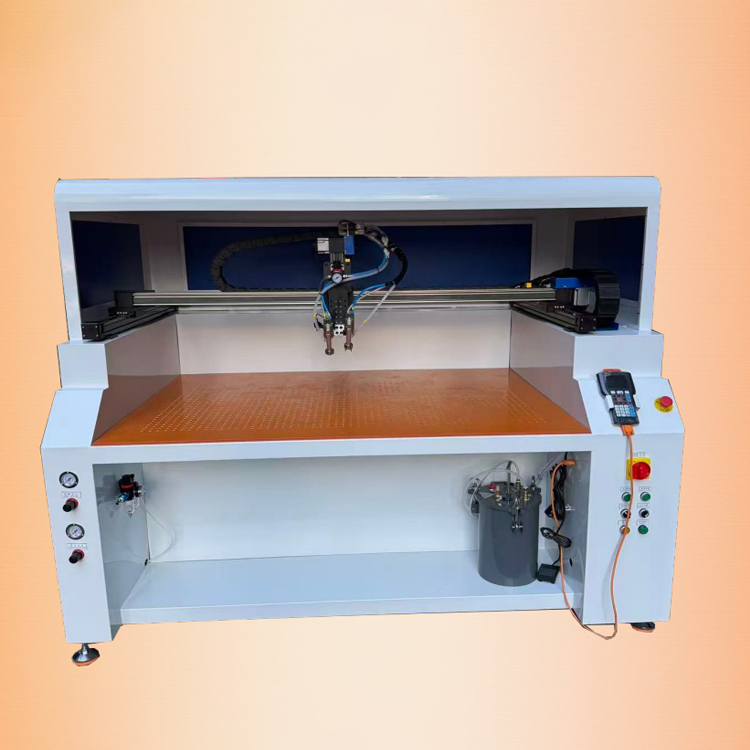

JL-685 Fully automatic glue edge folding machine

Description

Product Features:

1. Fast speed (maximum speed reaches 3000 rpm, maximum stroke length 25 mm)

2. Easy to operate: (Novice operators can operate the machine without any problems for the first time; no production experience is required; the machine automatically senses the operator’s proficiency and adjusts itself accordingly)

3. Automatic gluing: The machine automatically dispenses glue as it folds the edge. The amount of glue is automatically adjusted based on the folding speed, and can also be adjusted manually.

4. Automatic speed change: Using infrared detection, the machine automatically senses when the material is about to bend and automatically slows down when the bend occurs, resulting in a rounder, more perfect bend.

5. Automatic constant temperature: The machine automatically heats up upon startup and automatically maintains a constant temperature (130°-150°C), saving 30% of electricity.

6. A computer chip-based circuit system is used, with a stepper motor controlling the internal, linear, and external bending pitch functions.

7. A touchscreen digital display control panel allows for infinite adjustment of the dissolution temperature, dispensing temperature, dispensing flow rate, and dispensing temperature.

8. Automatic internal bend cutting provides dual protection for the dispensing system.

9. The folding width is adjustable from 3mm to 6.5mm, and reinforcement tape can be folded in.

10. A servo motor automatically adjusts positioning, saving 40% of energy.

Industry application: leather product factories such as shoes, bags, wallets, and electronic product cases.

Product Specifications

Voltage: 220V

Motor Power: 1KW

Dimensions: 1200*600*1150mm

Net Weight: 90kg