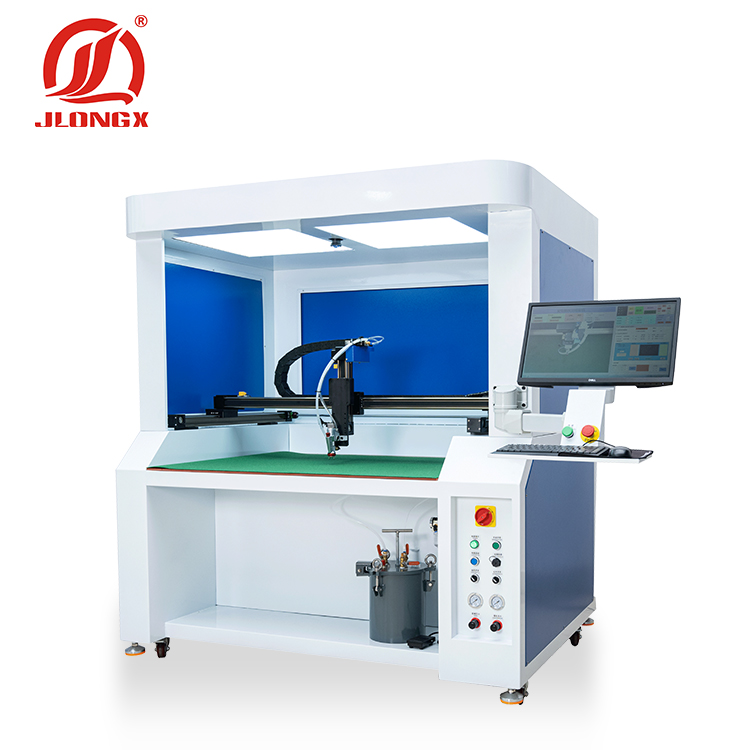

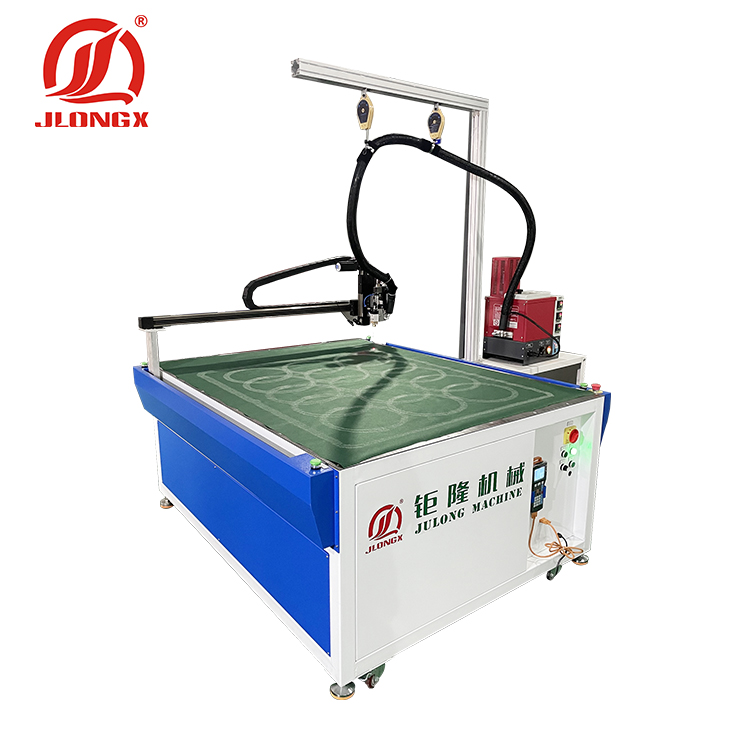

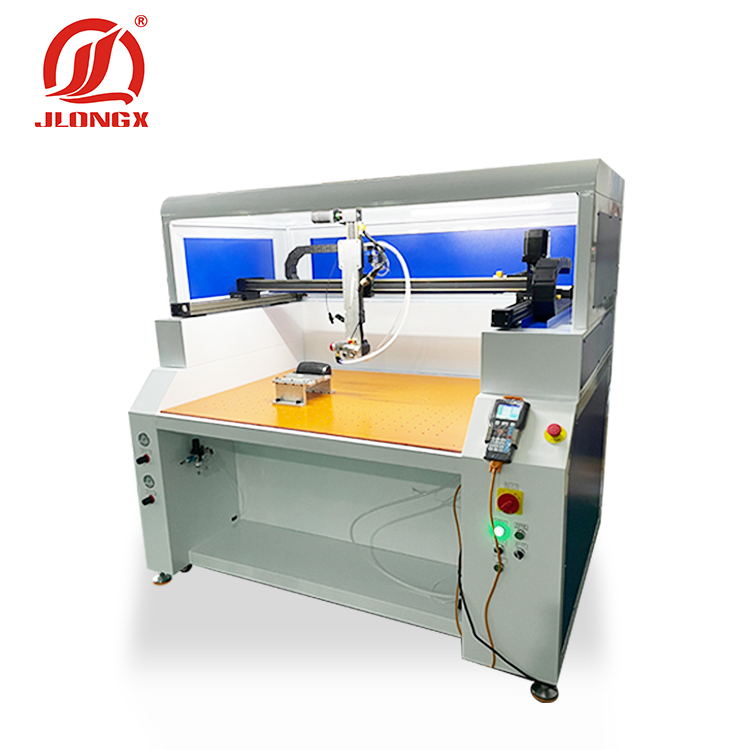

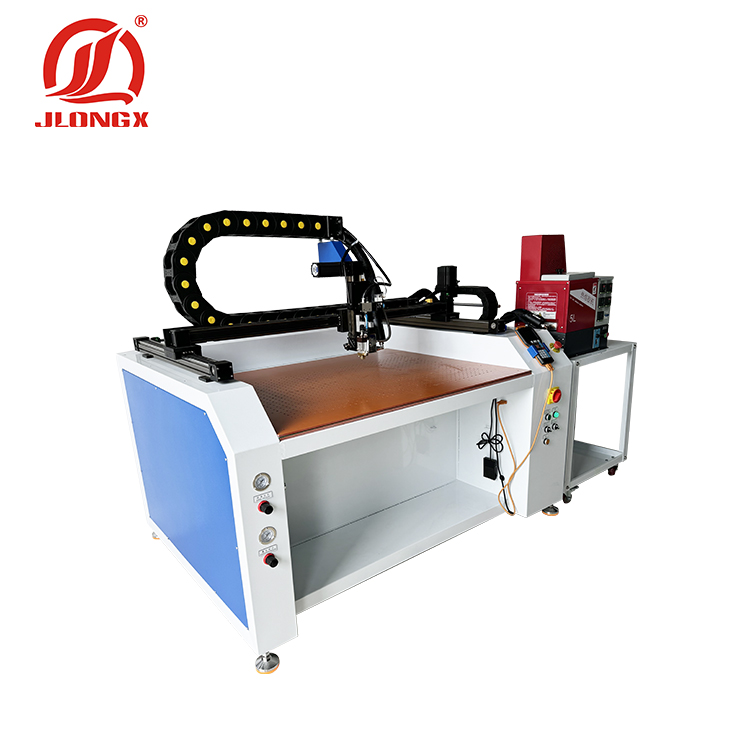

JL-10060GD Computer vision glue spraying machine

Description

Product Features:

1. Large Range: The spraying range is 1 meter long and 60 cm wide.

2. All-Sheet Metal Frame: The frame is a welded sheet metal structure that will not deform during long-distance transportation. No assembly is required, just plug in and use.

3. Automatic Identification: The machine uses a 25-megapixel camera that can capture and identify the material’s outline within 1 second and generate a spraying path.

4. No Pattern Required: No need to edit or create a pattern. Simply place any shape or color on the machine platform and the machine will recognize the product’s path. No need to save or import drawings.

5. Free Drop: Materials can be Place the material anywhere in the machine; there’s no need for a fixed location; the machine will automatically find it.

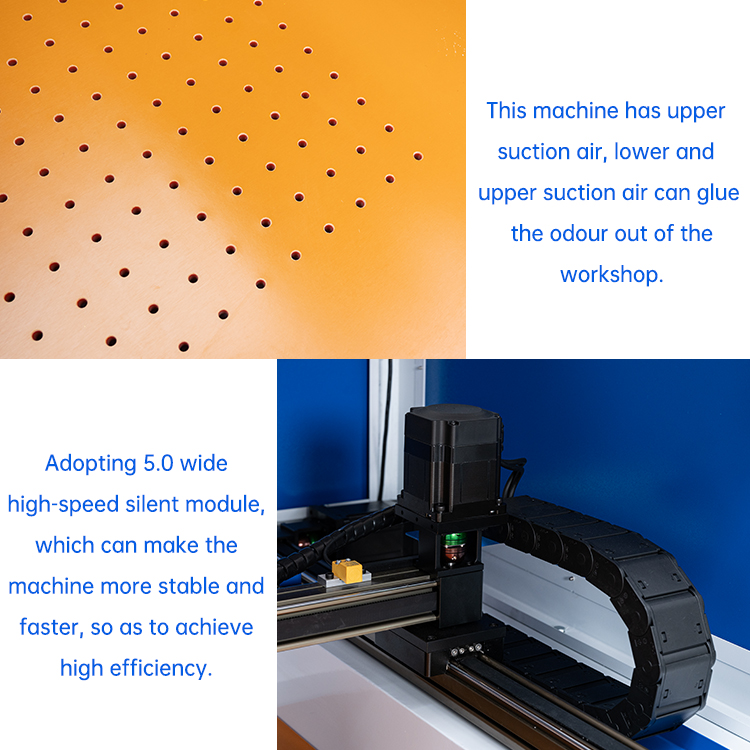

6. Automatic suction: The machine is equipped with three fans for suction, which absorbs the material and prevents it from moving during operation.

7. Module: A 5.0mm wide, high-speed, silent module is used, ensuring smoother and faster operation, resulting in higher efficiency.

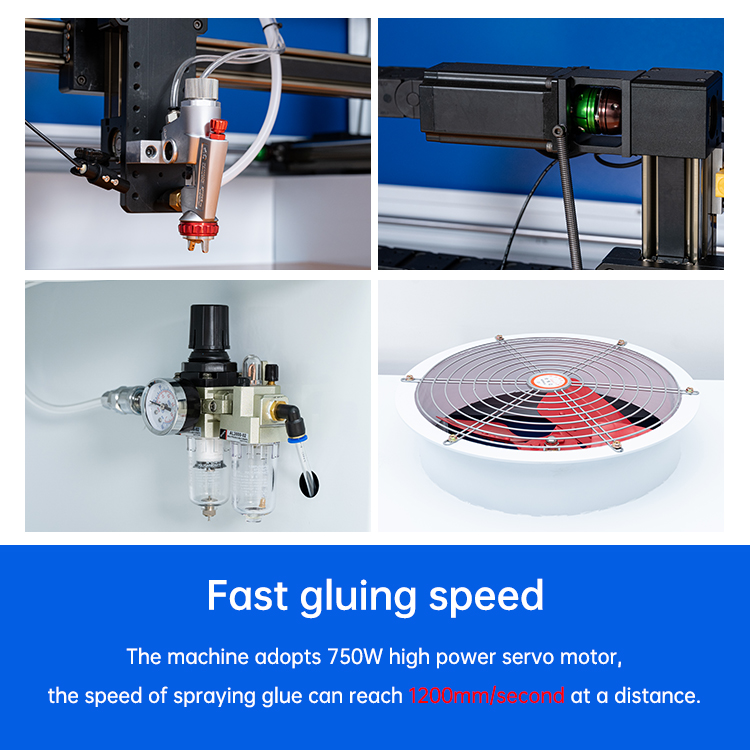

8. Fast speed: This machine uses a 750W high-power full servo motor, achieving a maximum glue spraying speed of 1200 mm/s per distance.

9. Improved efficiency and labor cost savings: The fast coating speed can save 5-8 people, effectively improving production efficiency and reducing labor costs.

10. Reduced glue consumption and reduced costs: The stable operation and controlled glue application system feature an adjustable glue spray head that can adapt to different glue spraying widths, allowing for 3-15mm glue sprays along the material.

11. High operating efficiency, uniform and thin glue spraying, saving approximately 20% glue and achieving high returns.

12. Convenient operation, automatic material conveying, and visual automatic positioning. A vision system is a set of equipment that uses visual information to perform specific functions.

The purpose of adding vision sensors is to enable the equipment to possess human-like vision capabilities, thereby increasing its intelligence and improving production line efficiency and product quality. Machine vision can be used to perform tasks in hazardous environments unsuitable for humans or where the human eye struggles to meet quality requirements.

Therefore, machine vision technology can enhance the automation and flexibility of production lines. Using cameras to automatically capture the contours of workpieces, it reduces rounding errors and is simple and easy to understand.

13. Widely adaptable: Within the effective spraying range, it can identify materials of different colors, shapes, and positions, better adapting to the varying material characteristics required during the production process.

14. Environmentally friendly and energy-saving: The equipment features an exhaust system to remove glue odors generated during spraying.

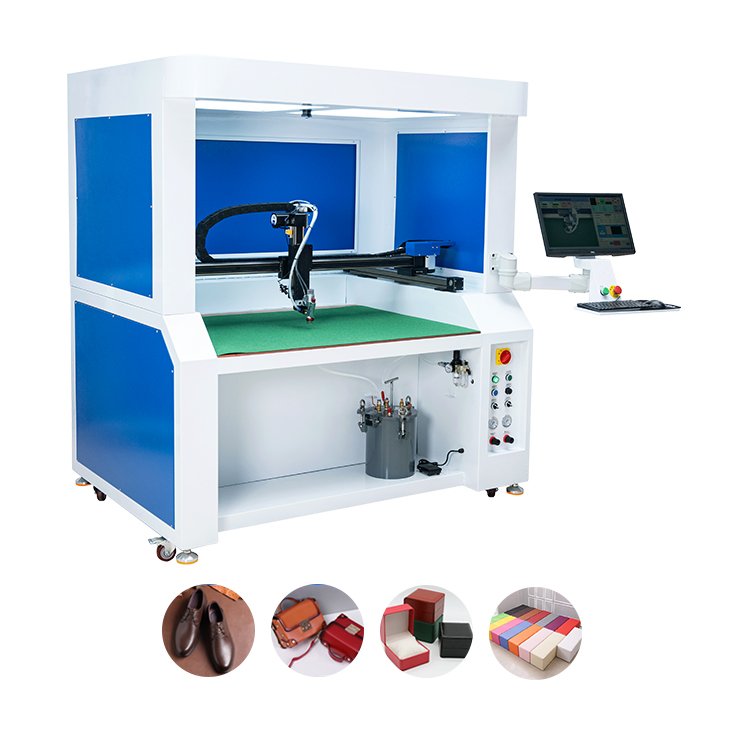

Applicable to:

shoe factories, luggage factories, leather bag factories, gift jewelry packaging box factories, leather goods factories, electronic product leather case factories, jewelry factories, furniture factories, glasses case factories, automobile interior decoration factoriesand other industries.

Product Specifications

Spray Width: 1000 x 600mm

Voltage: 220V

Motor Power: 4kW

Dimensions: 1700 x 1250 x 1900mm

Net Weight: 350kg